50

Years

3000

m2

ISO

9001:2015

Qualified process

We provide specific solutions to the most stringent requirements. We are flexible, and adapt our forming process to your needs.

We undertake the entire pipe transformation process:

Industrial expertise in high-end manufacture of products in a range of materials:

We add any component to be attached subsequently:

Innovation in forming processes

Flexibility in batch sizes

Speedy delivery of samples

Speedy logistics during mass-production phase

High quality standards

Analytical engineering

We are with you throughout the entire process

Our highly qualified team, which undergoes training on a constant basis, applies its forming know-how to come up with the best solution for each case

Prototype, sample and pre-production phases

We carry out prototype, sample and pre-production phases for the purpose of obtaining empirical and analytical results, to enable us to control exogenous factors and also internal factors in the pipe transformation process. These analyses are carried out alongside engineering work for our customers, and they are essential for components with major technical requirements.

Implementation of the production process

We reach the mass-production phase, during which we control the process parameters and apply the quality controls necessary to obtain parts matching our customers’ technical requirements. We use a number of systems to guarantee the sealing on the pipes we form. We work with regular production programmes or to order, adapting our work to the production and logistics requirements of our customers.

Large adaptable facilities

The flexibility of our facilities enables us to undertake both small and large volumes of production, adapting to changes in our customers’ plans on an extremely competitive basis.

Means of production

Automatic saws

to cut pipes up to diameter 90 mm.

NC benders

up to diameter 32 mm.

NC benders

right-left up to diameter 22 mm.

NC benders

right-left up to diameter 42 mm.

NC benders

up to diameter 60 mm.

Pipe benders

from coil up to diameter 18 mm.

Flaring machines

up to diameter 40 mm.

Punching systems

Various punching systems.

Mechanical presses

up to 60 Ton.

Pillar drills

Several pillar drills and T-Drill.

Ancillary machinery

bridge crane up to 6 Ton.

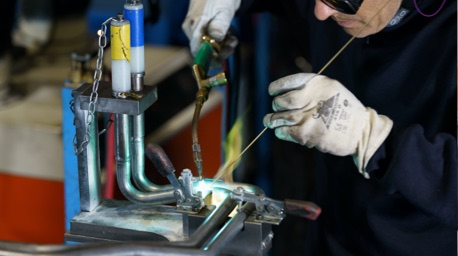

Several welding stations

TIG, MIG, Oxyacetylene, Induction

Welders approved in UNE EN 15085-2 for copper

Sealing control

Leak sensor 2 -30 bars of pressure.

3D laser arm

High-accuracy 3D laser arm with reverse engineering

Industries

We create customised solutions for strategic sectors

Trust

Efficient, high-quality team work

Quality is an essential factor at Nemesio Zubia. We apply the necessary rigour and controls to each project in order to secure the best possible result in the finished product.

Since it was incorporated, Nemesio Zubia has had a reputation for commitment and proximity to the customer. Our location in Debagoiena has enabled us to build relationships of proximity, leading us to standardise and apply good practices with other customers, making us a European role model in metal pipe bending solutions. As Chief Executive Officer, I home in on initiative and a proactive attitude to undertaking projects and driving them forward, keeping ahead of any difficulties that may arise, and this is only possible thanks to all those who are a part of Nemesio Zubia.

My personal and professional background has always been connected to Nemesio Zubia. Origins, enthusiasm and sacrifice are values I have experienced at home since I was a child. I joined Nemesio Zubia after completing my studies in mechanical engineering, and over the last 25 years I have undertaken many challenges and headed up many projects, the most recent of which is my current position as Head of the Industrial Division. I have been with the company during these years of growth, and I have seen good times and other times which were more difficult and beset with uncertainty; but we have always come through, with much awareness of our customers’ needs, striving to provide them with value through our products. This has been and still is our raison d’être.